Efficient Maintenance Tips & Strategies for Commercial Refrigeration Systems

Imagine you’re a grocery store owner, and it’s the busiest day of the year—the day before a major holiday.

Your shelves are stocked with fresh produce, dairy, and meats, ready to meet the high demand. Families are counting on you for their holiday feasts.

Then, without warning, your commercial refrigeration system fails.

Within hours, your perishable inventory is at risk, and so is your reputation.

The holiday rush becomes a crisis, and you face the grim reality of spoilage, waste, and lost revenue.

This isn’t just a hypothetical scenario; it’s a cautionary tale that underscores the critical role of routine maintenance in commercial refrigeration systems.

Whether you’re running a grocery store, processing and packaging food, or processing chemicals, these systems are not just cooling units; they are the backbone of your business, ensuring that your perishable goods—and your profits—stay fresh.

Neglecting regular maintenance is a gamble you can’t afford, a ticking time bomb that can explode at the most inconvenient times, jeopardizing your inventory and reputation.

This guide will equip you, the savvy business owner or facility operator, with the essential knowledge and actionable strategies for maintaining your commercial refrigeration system.

From DIY tasks to the compelling advantages of outsourcing specialized care to professionals like Gateway Mechanical Services, we’ve got you covered.

So, if you’re serious about safeguarding your business and boosting your bottom line through optimal refrigeration system performance, you’re in the right place.

Let’s dive in and turn that ticking time bomb into a well-oiled machine that dependably serves your business daily.

Importance of Routine System Maintenance in Commercial Refrigeration Systems

Before we dive into the finer points of how to maintain your commercial refrigeration systems, we need to talk about what types of systems we’re talking about and why you should maintain them.

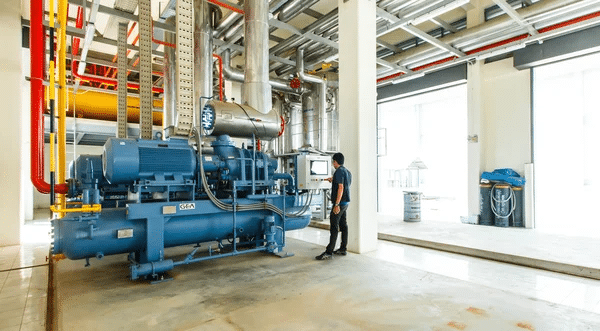

What Are Commercial Refrigeration Systems?

As a business owner or facility operator, you know that commercial refrigeration systems are not just any cooling units.

These are your silent partners in ensuring your perishable goods remain in optimal condition, minimizing waste and helping your business or production facility meet its financial goals.

Unlike the fridge in your home, these systems are engineered for heavy-duty, around-the-clock operation and come in various configurations to suit your specific needs—be it walk-in coolers for your restaurant or industrial freezers for your manufacturing facility.

The Impact of Maintenance on Energy Efficiency

Think of regular refrigeration maintenance as an investment, not an expense.

A well-maintained refrigeration system doesn’t just last longer; it also functions at its highest potential and helps ensure peak commercial refrigeration energy efficiency.

This translates to lower energy consumption and, by extension, reduced utility bills—a critical factor in improving your bottom line.

On the flip side, a neglected system has to work overtime, consuming more energy and inflating your operational costs.

How Routine Maintenance Improves Refrigeration System Safety

When it comes to commercial refrigeration, safety isn’t just a buzzword—it’s a necessity.

A poorly maintained system can become a breeding ground for bacteria, putting your products and, ultimately, your customers at risk.

If left unmonitored, neglected systems will fail more frequently, resulting in additional lost product and time.

In addition, electrical issues or malfunctioning components can pose serious safety hazards to your staff.

Regular maintenance checks can identify and rectify these issues before they escalate, ensuring a safer work environment.

Repairing a problem in its early stages is always more affordable than fixing issues that have been developing for an extended period.

No matter how you look at it, failing to implement maintenance strategies for your refrigeration systems will eventually cost you more money than being proactive.

What Are the Benefits of Outsourcing Regular Maintenance to a Trusted Professional?

Finally, before diving into the maintenance tips and details, we want to discuss options to help you implement proactive, effective routines for your business or facility.

You’re an expert in running your business, not refrigeration mechanics—and that’s perfectly okay.

Outsourcing maintenance to a qualified professional like Gateway Mechanical Services allows you to focus on what you do best.

Our expert technicians bring a wealth of experience and specialized tools, ensuring your system receives the thorough, high-quality care it deserves.

Plus, a professional can spot issues that might go unnoticed, saving you from potential headaches.

So, if any of the concerns we discuss in this guide sound overwhelming or you’re worried about the cost of training or expanding existing maintenance staff, know that you can always count on a reliable third-party maintenance provider to help!

Basic Commercial and Industrial Refrigeration System Maintenance Considerations

Now that you know why maintenance should be essential to running your business and using commercial refrigeration equipment, we can explore the many maintenance opportunities you might have.

Not all of our discussed points will apply to every refrigerator system. However, we’ve included the most common tasks to ensure this guide is as valuable as possible.

If you have any questions about the exact maintenance requirements for your system, don’t hesitate to reach out to us for a personalized consultation!

Cleaning the Condenser Coils

Think of the condenser coils as the lungs of your refrigeration system.

When they’re clogged with dust, dirt, and debris, your system must work harder to maintain the desired temperature, increasing energy consumption and wear on components.

A monthly cleaning is highly recommended to keep your system running efficiently.

To clean the coils, turn off the power to your refrigeration unit for safety.

Then, gently use a soft-bristle brush to remove loose debris from the coils.

You can use a commercial coil cleaner, following the manufacturer’s instructions for a deeper clean.

After applying the cleaner, use a low-pressure vacuum or compressed air to remove any remaining particles.

Finally, turn the power back on and monitor the system to ensure it’s working as expected.

Checking the Door Gaskets for Leaks

Door gaskets are the unsung heroes of your refrigeration system.

They form a seal that keeps the cold air in and the ambient air out.

Over time, these gaskets can wear out or become damaged, leading to air leaks and inefficiency.

At least once a month, inspect the gaskets for cracks, tears, or signs of wear.

You can perform a simple paper test: close the door on a printer or notebook paper sheet and try to pull it out.

If it slides out easily, your gaskets likely need replacing.

Defrosting the System Regularly

Defrosting is essential, especially for systems without an automatic defrost cycle (more on this later.)

Ice buildup can insulate the evaporator coils, causing your system to work harder and consume more energy.

Defrosting frequency depends on your refrigeration system and how heavily it’s used.

For manual defrost systems, aim to defrost whenever the ice buildup reaches a quarter-inch thickness.

Always follow the manufacturer’s guidelines for both manual and automatic defrost cycles.

Monitoring the Temperature and Humidity Levels

Temperature and humidity control are at the core of your refrigeration system’s function.

Daily monitoring is crucial to ensure that your perishable goods are stored optimally.

Most modern systems come with built-in digital thermometers and hygrometers, but it’s good practice to have an independent thermometer as a backup.

If you notice any significant fluctuations, it could be a sign that your system needs attention.

Keeping the System Free of Debris and Pests

Your refrigeration system is not an island; it’s part of your overall facility.

Keeping the area around it clean is just as important as maintaining the system.

Ensure that there’s no buildup of debris, dust, or waste materials around the unit.

Also, be vigilant about pest control. Rodents or insects can damage the electrical wiring and insulation, leading to costly repairs.

Advanced Commercial and Industrial Refrigeration System Maintenance Considerations

While there are many elements of regular maintenance you can likely handle yourself, some tasks and considerations are best left to professionals.

In this section, we’ll look at considerations that you should definitely consider outsourcing to a trusted service provider to keep your refrigeration system running smoothly and efficiently.

Checking the Refrigerant Levels

Low refrigerant levels are more than just an operational hiccup; they’re a safety concern.

Insufficient refrigerant can increase temperatures, putting your perishable goods at risk.

Moreover, refrigerant leaks can be harmful to the environment.

A quarterly check by a certified technician not only ensures compliance with environmental regulations but also safeguards the quality of your stored products, giving you peace of mind, ensuring your refrigeration systems run like clockwork, and saving you both time and money.

Lubricating the Compressor Bearings

The compressor is the heart of your refrigeration system, and its bearings need regular lubrication to function smoothly.

Failing to do so can lead to wear and tear and, in worst-case scenarios, a complete system breakdown—a costly and potentially dangerous situation.

An annual lubrication, performed by a skilled technician, ensures that your compressor runs efficiently and safely, extending the lifespan of your system and reducing the risk of unexpected, costly repairs.

Optimizing Automated Defrost Cycles

Automated defrost cycles are a feature, not a guarantee of efficiency.

If not calibrated correctly, they can either run too frequently, wasting energy, or too infrequently, leading to ice buildup and potential spoilage.

A qualified technician can optimize these cycles to match your specific needs, improving energy efficiency and reducing the risk of product loss due to temperature fluctuations.

The result? A more reliable system that operates at peak efficiency, saving you money in the long run.

Inspecting the Electrical System for Any Signs of Damage

Electrical issues should not be taken lightly.

They can lead to system failures and pose serious safety risks, including electrical fires.

A certified technician’s annual electrical system inspection can identify frayed wires, loose connections, or other potential hazards.

This proactive approach not only ensures the safety of your staff and facility but also prevents costly emergency repairs and ensures seamless operation, allowing you to focus on growing your business, not putting out fires—literally and figuratively.

Testing the Safety Devices

Safety devices like pressure relief valves and overload protectors are your last defence against system malfunctions.

An annual test of these devices is crucial to ensure they function as intended when needed.

Failure to do so can result in catastrophic system failures, posing significant safety risks.

By investing in this annual check, you’re investing in the safety and reliability of your entire operation.

Benefits to Consider When Deciding If Outsourcing Refrigeration System Maintenance is a Good Fit for Your Business

As mentioned, it often doesn’t make sense for businesses to rely on employees to conduct the more advanced routine maintenance tasks required to keep a commercial refrigeration system running at peak efficiency.

However, if you’re still on the fence, consider the following benefits of outsourcing maintenance and see if they align with your operational or business goals.

Access to Experienced and Qualified Technicians

When you outsource maintenance to a trusted professional like Gateway Mechanical Services, you’re not just hiring a service but gaining a partner in efficiency and safety.

Our technicians bring years of specialized experience and are equipped with the latest diagnostic tools.

This expertise translates to quicker problem identification and resolution, minimizing downtime and maximizing operational efficiency.

Better still, we can customize your maintenance plans to ensure you have access to our experts exactly when you need them.

From monthly check-ups to annual plans, our flexible options ensure you can always find the perfect solution for your business.

Peace of Mind Knowing That Your System Is Being Properly Maintained

A certain peace of mind comes with knowing your refrigeration system is in expert hands.

Regular maintenance by a certified technician ensures that every system component functions optimally.

This proactive approach reduces the risk of unexpected breakdowns, allowing you to focus on your core business activities without worrying about system failure.

Reduced Risk of Breakdowns and Costly Repairs

An ounce of prevention is worth a pound of cure.

Regular maintenance can identify potential issues before they become major problems, saving you from the nightmare of a system breakdown during peak business hours.

The result? Lower maintenance costs in the long run and a system that you can rely on, day in and day out.

Extended Lifespan of Your System

Regular maintenance doesn’t just keep your system running; it keeps it running for longer.

By addressing minor issues before they escalate, you’re extending the lifespan of your system.

This means fewer capital expenditures on new equipment, reduced downtime to account for equipment replacement, and more money in your pocket.

Frequently Asked Questions about Maintenance Strategies for Commercial Refrigeration Systems

How Often Should I Have My Commercial Refrigeration System Maintained?

The frequency of maintenance depends on various factors, including the type of system and its usage.

However, a general rule of thumb is to schedule a professional check-up at least quarterly for optimal performance and safety.

As this guide outlines, you should perform regular, smaller tasks like cleaning and temperature monitoring more frequently.

What Are the Signs That My Commercial Refrigeration System Needs Maintenance?

Warning signs include fluctuating temperatures, strange noises, and higher-than-usual energy bills.

These could indicate issues ranging from minor adjustments to more severe problems that require immediate attention.

What Are the Risks of Not Properly Maintaining My Commercial Refrigeration System?

Neglecting maintenance can lead to many issues, including increased energy consumption, reduced system lifespan, and even potential safety hazards like electrical fires or spoiled goods.

In short, poor maintenance is a risk you can’t afford to take.

What Are the Benefits of Outsourcing Regular Maintenance to a Trusted Professional?

Outsourcing to a professional like Gateway Mechanical Services offers several advantages, including access to specialized expertise, peace of mind, and cost savings through preventive care and extended system lifespan.

How Much Does It Cost to Have My Commercial Refrigeration System Maintained?

Maintenance plans are an investment in your business’s smooth operation and long-term success.

The cost of maintenance can vary depending on the complexity of your system and the services required. As such, we can’t provide any estimates in this guide.

Gateway Mechanical Services offers customized plans to fit any budget. If you’re curious about the costs of maintaining your system, reach out today to discuss the specifics with one of our analysts.

What Are Some Tips for Choosing a Qualified Commercial Refrigeration System Maintenance Provider?

Look for providers with a strong track record, certified technicians, and transparent pricing.

Recommendations from other business owners in your industry or online business profiles can also be invaluable.

What Should I Do If My Commercial Refrigeration System Breaks Down?

In the event of a refrigeration system failure, the first step is to call a trusted professional for immediate repair.

Meanwhile, take measures to preserve the integrity of your perishable goods, such as transferring them to a backup system if available.

Conclusion

Regular maintenance of your commercial refrigeration system is not just a recommendation; it’s necessary for safety, efficiency, and longevity.

Each maintenance activity is crucial, from basic tasks like cleaning the condenser coils to more in-depth checks like optimizing automated defrost cycles.

Outsourcing these tasks to a trusted professional like Gateway Mechanical Services offers invaluable peace of mind and long-term cost savings.

Don’t leave the efficiency and safety of your commercial refrigeration system to chance.

Contact Gateway Mechanical Services today for a free consultation and take the first step towards a more reliable, cost-effective operation.