Hydronic Heating and Cooling: The Definitive Guide

There’s a lot going on inside the walls of your home or office. Like the veins and capillaries under your skin, modern buildings are laced with heating and electrical systems designed to keep your home well-lit and temperate throughout the extremes of the Canadian climate. Today we want to introduce you to (or refresh your memory about) hydronics, the basis of some of the most common heating and cooling systems in use today.

By the end of this guide, you’ll have ready answers to common questions like the following:

- What is a hydronic heating system?

- How does hydronic heating work?

- Why choose hydronic heating?

- Is hydronic heating efficient?

- Is hydronic heating more efficient than forced-air?

- How much does it cost to install hydronic heating? And when should you look into recommissioning?

- What to avoid when designing a hydronic heating system

Feel free to use the links above to skip directly to the question that’s foremost on your mind, or tuck in for the whole enchilada.

What is a hydronic heating system?

Let’s begin to answer that question by defining hydronics.

It’s likely that the first method primitive man discovered to heat up a space was simply lighting something on fire inside of it (ideally this would be in a fireplace, but hey it’s your life). The energy given off by the flame would then radiate through the air, creating a cheery warmth–in this case, the air itself is the heat-transfer medium.

Hydronic systems by contrast circulate liquid via piping as a heat-transfer (or cooling-transfer) medium, with water and glycol being the most common liquids in use. We’ll get into more detail on how they work in the next section, but by way of a general example, a standard hot-water radiator will likely be the hydronic system most familiar to the reader.

These systems can be roughly divided into hot water and chilled water types, but there is a wide variety of different possible configurations which are classified according to their piping arrangements, pressurization, flow generation and temperature capacity.

In larger-scale installations, such as high-rises or large commercial spaces, both hot and cold water will be piped in a loop through all of the radiators in the building, allowing the system to heat and air condition rooms as needed.

How does hydronic heating and cooling work?

The easiest way to summarize how hydronic systems work is by describing its most basic application: the single-pipe steam radiator.

Steam radiators work by heating water with a boiler until it becomes vaporous. The steam is forced through a single pipe into a radiator (or series of radiators), where it gives up its heat and condenses back into water. Radiators are located close to the wall in order to produce an air convection current which circulates the heat around the room. Meanwhile, the condensed water runs backward down the piping, returning to the boiler to be heated again as needed.

Steam radiators are inexact and inefficient compared with liquid water-based hydronics systems, and as such have been replaced in most contemporary applications. Most systems now use electrical pumps (rather than gravity) in order to circulate heated or cooled water throughout the building, and insulation is used to manage heat flow and condensation.

Types of hydronic systems

| Low-temperature water (LTW) | < 250°F |

| Medium-temperature water (MTW) | 250°F to 350°F |

| High-temperature water (HTW) | > 350°F |

| Chilled water (CW) | 40°F to 55°F |

| Dual-temperature water (DTW) | LTW and CW |

The hydronic systems installed in most commercial buildings today are either low-temperature (LTW), chilled-water (CW), or dual-temperature (DTW).

As this is a “layman’s” guide, we won’t be getting too deep into the technical nitty gritty, but if you’re curious about the details of piping, pumps and terminal units (ex. radiators, heating/cooling coils in AC units), Insulation.org has written a readable and authoritative overview.

Why choose hydronic heating?

There are a number of significant advantages to choosing hydronic heating and cooling, as well as some important drawbacks.

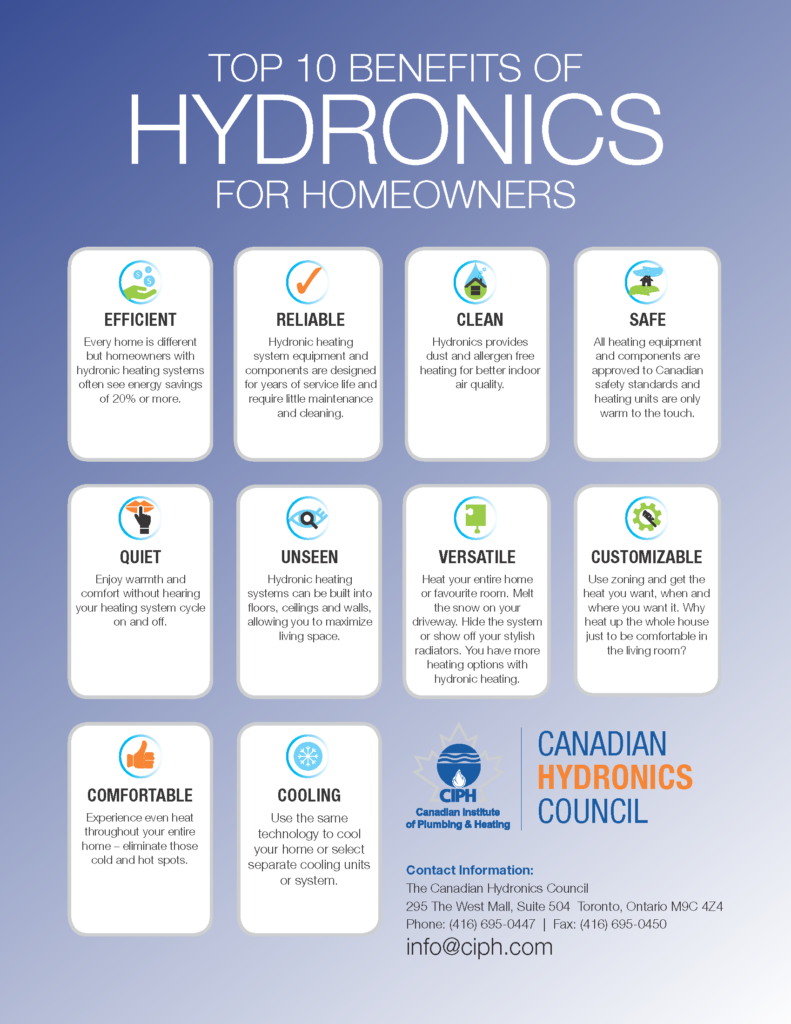

On the Pros side of the fence, the Canadian Hydronics Council (CHC) has prepared an infographic that neatly summarizes the primary benefits:

Now, granted, the CHC is an industry trade group, so they do have some vested interest in singing the praises of hydronic technology, but in our own experience these systems are indeed versatile, quiet, clean and inexpensive to operate–not to mention extremely safe, provided that equipment is properly installed and regularly serviced.

On the other hand, hydronic systems do little to address humidity, and they can result in stagnant air as there is no ventilation. In some installations, hydronic systems are combined with air systems to mitigate these issues.

Is hydronic heating efficient?

It is! In general, less energy is required to circulate water than to force air through ducts (see section below). Radiators will also typically remain warm for some time after the boiler has been turned off, allowing you to cruise along on residual heat at strategic intervals and thereby moderate your energy consumption. Because the heat-transfer liquid is continuously recycled within the system, resource consumption is limited. Ultimately, the primary cost will be to power the electrical pumps and central heating/cooling apparatus (i.e. the boiler or equivalent). With proper installation and insulation these costs can be significantly mitigated.

Is hydronic heating more efficient than forced air?

As the Government of Yukon notes in their hydronics fact sheet, “a small volume of hot water will deliver the same amount of heat as a large volume of warm air. Heating air, rather than water, requires ductwork many times larger than a water-filled pipe.” What this means in effect is that hydronic systems are often considerably less intrusive than installing ductwork, as they require less space and can be integrated easily into existing structures.

One case where forced air is the clear winner is in large open-concept commercial spaces, such as big box department stores. Because the lion’s share of the building is comprised of a single large room, it’s considerably easier in most situations to just drop some forced air units on the roof to heat and cool the space than to run water lines throughout the building.

Whether a hydronic system is a better fit for you than a forced-air system ultimately depends on your building’s needs, and whether you value the benefits of hydronics enough to overlook what drawbacks there are.

How much does it cost to install hydronic heating? And when should you look into recommissioning?

These costs will vary considerably based on the type of system and the size of the building in question–it’s best to discuss these details with a technician to determine whether hydronics is the right choice for your needs.

In older buildings, we often find that a thorough recommissioning of the system can add many years to the life of a troublesome hydronics installation, at a fraction of the cost of a full overhaul. A recommissioning is a bit like hitting the reset button. In most cases, maintenance focuses on the repair or replacement of individual components, with less of an eye to the workings of the system as a whole.

Over time, you will often end up with a bit of a Frankesteined system of random, imperfectly compatible parts, which puts strain on overall functionality. After a recommission, your system will be returned to its intended state.

As part of the process, a technician will first perform an efficiency evaluation, checking out things like…

- Gas pressure

- Cleanliness of burners

- Electrical elements

- Pump efficiency

- Air volume

This evaluation can usually be performed within a day. From there you can discuss your options going forward, and lock in a regular service schedule to keep everything working optimally.

What should you avoid when designing a hydronic heating system?

Our technicians strongly recommend customers purchase appliances and parts that are commonly available. Look for products that are domestically sourced; some HVAC companies may push for you to use parts from less well-established suppliers they have business relationships with, which can cause compatibility issues down the line when it comes to servicing and replacing elements of your system.

It’s also important to choose the right appliance for your needs. One of the most common problems our repair experts see involves in-floor heating. These systems use low temperature water (LTW), averaging 80 to 90°F, which require a high-efficiency boiler for proper functioning. All too often, a generic atmospheric boiler has been installed instead. Atmospheric boilers require a return water temperature of at least 130°F–lower temperatures will cause the heat exchanger to warp, necessitating repeated and costly repairs over time.

This example serves as a reminder that you should always make sure to go with a reputable company with a proven background in hydronics design.

Conclusion

We hope this has answered a few of your most burning (or chilling?) questions about hydronics. As Western Canada’s HVAC leader, Gateway is committed to doing what we can to make sure good information is out there for facility managers and property owners. Our technicians are always ready to help you find the heating and cooling solution that will provide you the cleanest and most efficient value for your dollar.

If there’s a question raised here you’d like to know more about, or there’s something we might’ve missed, feel free to ask us in the comments or drop us a line at 1.800.414.4929 and we’ll do our best to help you out.

You can also let us know what topics you’d like us to cover in future!

See you next time!